Products

Embedded optical fiber connector RM-ESC

RM-ESC series fiber optic quick connectors are used to solve the problem of fiber optic termination joints made on site for direct connection to optical cat equipment. This type of fiber optic connector uses pre embedded fiber optic to ensure low optical attenuation index and stable performance after fiber termination. It can be used to make SC/PC (APC) and FC/PC (APC) fiber optic connectors. Quick connectors are not only suitable for single mode or multimode fiber optic cables, but also have an installation process of less than 2 minutes, This connector system does not require any adhesive or curing process, making it the best choice for fiber optic cables entering the home for quick termination and on-site installation with fewer tools

Technical Principles

The design principle of a fast connector is to cut the bare optical fiber through a professional fiber cutting knife at a fixed length to obtain a neat fiber end face. Then, the bare optical fiber is inserted into a high-precision V-shaped groove, and a high-precision ceramic insert is introduced to seamlessly connect with the pre embedded finished bare optical fiber, achieving physical hard connection. Then, the tail bare fiber and outer skin are fixed in three layers, and a slightly bent bare fiber is reserved to ensure thermal expansion and contraction The internal length change caused by tensile force changes is elastically fixed to the bare fiber and coating layer through a metal U-shaped clamp spring, which is not sensitive to temperature changes and ensures that the optical performance does not change under high and low temperature conditions. The three-layer fastening method of tightening the bare fiber, coating layer, and optical cable sheath, with a tensile resistance of up to 50N/10 minutes, ensures high stability, low attenuation, and high efficiency in various application scenarios.

Application Scenario

Product Features

- On site installation with less use of tools or no need for special tools

- Easy and fast operation

- Can make fiber optic connectors of any length

- No need for any bonding and polishing process

- No need for fiber optic fusion, saving power

- Can be repeatedly installed more than 300 times

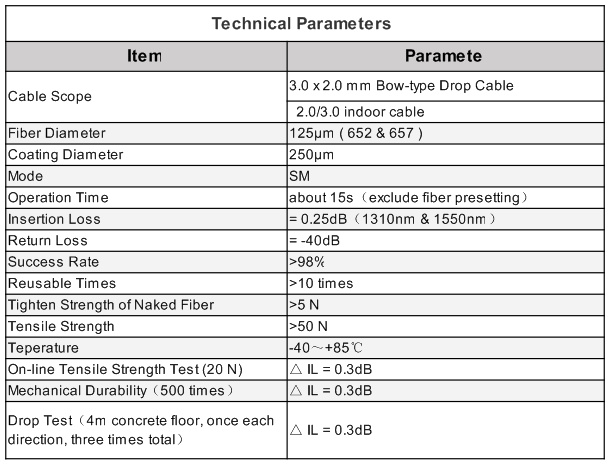

Technical Parameter

Series Products

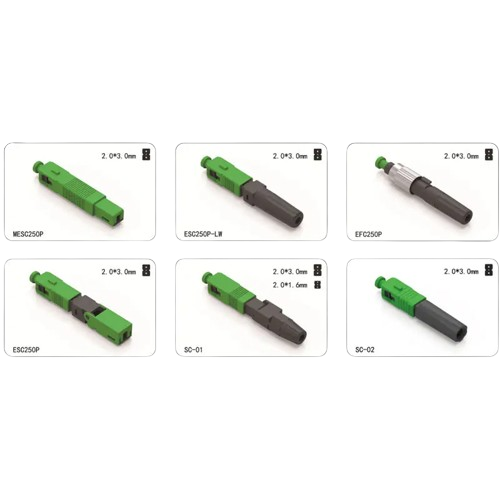

RM-ESC250D-APC

- 1. Double V-groove structure design ensures stable and reliable fiber optic docking

- 2. Core structure: Adopting a normally closed elastic fastening method, with excellent technical indicators;

- 3. Linkage structure design, with reserved slight bends remaining unchanged when docking with equipment and joints;

- 4. Applicable optical cable: 2.0*3.0mm, 2.0*1.6mm butterfly optical cable;

- 5. Coating diameter: 250μm;

- 6. Tensile strength: ≥ 30N;

- 7. Product length: 52mm.

RM-MESC250P-APC

- 1. Metal V-groove design, high fiber docking accuracy, and excellent technical indicators;

- 2. Core structure: Adopting a box masonry structure design, with good sealing performance, less loss of matching fluid, and strong weather resistance;

- 3. Applicable optical cable: 2.0mm × 3.0mm butterfly optical cable;

- 4. Tensile strength: > 40N/2min;

- 5. Easy to operate, fast construction speed, high installation success rate, long service life, and simple and convenient maintenance in the later stage.

- 6. Product size: 49.7*8.9*8.2mm, small product size, suitable for narrow space environments;

RM-ESC250P-LW

- 1. Applicable optical cable: 2.0 × 3.0mm butterfly optical cable;

- 2. Coating diameter: 250 μ M;

- 3. Metal V-groove;

- 4. Tensile strength: ≥ 40N;

- 5. Product length: 56.6mm.

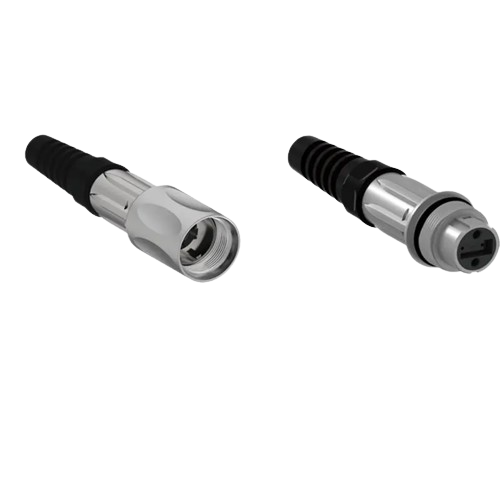

RM-ESC925T

- 1. Applicable optical cable: 2.0 × 3.0mm, 2.0 × 1.6mm butterfly optical cable Ф 2.0mm Ф 3.0mm yellow cable, Ф 0.9mm invisible optical cable;

- 2. Coating diameter: 250 μ m. 900 μ M;

- 3. Metal V-groove;

- 4. Tensile strength: 2.0* 3.0mm, 2.0* 1.6mm butterfly optical cable Ф 2.0mm Ф 3.0mm yellow cable ≥ 30N, Ф 0.9mm invisible optical cable ≥ 5N;

- 5. Product length: 53.5mm (excluding soft tail length)

RM-EFC250P

- 1. Applicable optical cable: 2.0 *3.0mm butterfly optical cable;

- 2. Coating diameter: 250 μ M;

- 3. Metal V-groove;

- 4. Tensile strength: ≥ 40N;

- 5. Product length: 53mm.

- 6. Metal V-groove design, high fiber docking accuracy, and excellent technical indicators;

- 7. Core structure: Adopting a box masonry structure design, with good sealing performance, less loss of matching fluid, and strong weather resistance;

RM-SC-APC-01

- 1. Applicable optical cable: 2.0 × 3.0mm, 2.0 × 1.6mm butterfly optical cable;

- 2. Coating diameter: 250 μ M;

- 3. Tensile strength: ≥ 30N;

- 4. Product length: 60mm.

RM-SC-APC-02

- 1. Applicable optical cable: 2.0 × 3.0mm butterfly optical cable;

- 2. Coating diameter: 250 μ M;

- 3. Tensile strength: ≥ 30N;

- 4. Product length: 50mm;

- 5. The product has a small volume and is suitable for narrow construction environments.

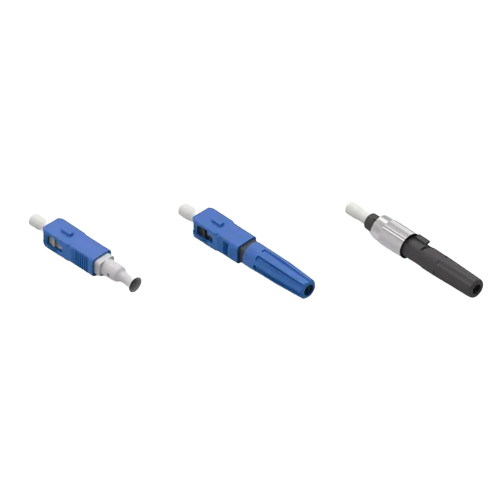

RM-ELC925T

- 1. Spiral type, suitable for optical cable: 2.0 * 3.0mm, 2.0 * 1.6mm butterfly optical cable Ф 2.0mm Ф 3.0mm yellow cable, Ф 0.9mm invisible optical cable;

- 2. Coating diameter: 250 μ m. 900 μ M;

- 3. Tensile strength: 2.0* 3.0mm, 2.0*1.6mm butterfly optical cable Ф 2.0mm Ф 3.0mm yellow cable ≥ 30N, Ф 0.9mm invisible optical cable ≥ 5N;

- 4. Product length: 40mm

Operating Steps (Example)

Repeat the opening steps

Packaging and Transportation

Butterfly optical cable stripper (Free gift)

Two in one toolbar (Free gift)

Fiber optic cutting knife (paid purchase)

Packaging and Transportation

This RM-ESC series of products adopts standard corrugated cardboard boxes, with fumigated wooden trays at the bottom and protective film wrapped on the outer layer.

Product Services

After sales service: This series of products comes in various models, suitable for various types of optical cables and various scenarios. Please consult our sales personnel for specific models. For contact information, please refer to the contact channels on our official website

Standard service: This series of products is a standardized product suitable for the construction of fiber optic communication networks in various countries around the world. If you need to learn more about fiber optic systems or other extended products, please contact our customer service personnel, and we will do our best to answer and serve you

Instructions for use: For customers who have already reached a cooperation agreement, if you encounter any technical problems during the use process, you can consult our sales personnel 7 * 24 hours. We will wholeheartedly serve you and provide the most professional technical guidance