Products

Intelligent charging pile

Main function

- Communication function

The charging pile has the function of communicating with the superior management system, and supports CAN bus, Ethernet, GPRS, 4G and other port communication modes. - Network payment function

Charging piles support a variety of payment methods such as third-party payment platforms and mobile phone payments, making payment more convenient for users. - Charging reservation

You can book charging service on the charging platform, reserve charging space for you in advance, - Remote monitoring and remote upgrade

The charging pile can realize background monitoring and remote online upgrade through the operation management syste

Main function

Communication function

The charging pile has the function of communicating with the superior management system, and supports CAN bus, Ethernet, GPRS, 4G and other port communication modes.

Network payment function

Charging piles support a variety of payment methods such as third-party payment platforms and mobile phone payments, making payment more convenient for users..

Charging reservation

You can book charging service on the charging platform, reserve charging space for you in advance.

Remote monitoring and remote upgrade

The charging pile can realize background monitoring and remote online upgrade through the operation management system.

Protection function

Abnormal data take proactive protection measures to ensure the safety of the charging process and the safety of the vehicle battery after charging.

Credit card payment function

Support to read contactless IC card, charging control and charging, charge deduction. (The above functions are only supported by the smart version)

Measurement function

Electric energy metering device built in charging pile can be used for electric energy metering.

Charging mode

Support automatic, timed, quantitative, quota and other charging modes.

Charging pile HD display

- ①Touch charging Settings

- ②Charge capacity display

- ③Charge timing display

- ④Charge charging display

- ⑤Vehicle status display

- ⑥Charging progress display

The graphene smart charging pile HD smart screen can display important data such as power consumption and billing details, and can also upload data to the management platform to provide convenience for later management, the display uses OLED technology, the display is clearer and the interaction is more convenient, providing users with a better operating experience, and the simplification of the operation makes it easier for people to get started without complex instructions.

Graphene anticorrosion

Graphene is a two-dimensional carbon nanomaterial, with excellent thermoelectric conductivity, and is also a completely zero permeability material, so it is widely used in anti-corrosion coatings, conductive coatings, anti-fouling coatings and fireproof coatings and other fields, the use of graphene coating technology to make charging piles achieve high corrosion resistance, can ensure long-term use in high salt, high humidity areas.

Graphene heat dissipation

With the increasing requirements of high power products for performance, portability and integration, the heat generated per unit area of the device increases rapidly. In order to transfer the heat in the device quickly, so that the device is not damaged due to high temperature, our company has developed graphene products with high thermal conductivity and infrared emission. The product presents the characteristics of macroscopic smooth and microscopic wavy radiation structure unit after the use of graphene coating film, greatly increasing the heat dissipation area and conductivity, enhancing heat radiation heat dissipation, and increasing the heat dissipation rate of the equipment by 10%.

Temperature and power relationship

Dc charging pile series

| 40KW | 60KW | 80KW | 120KW | 160KW | 200KW | 240KW | 280KW |

|

Maximum input current |

|||||||

| ≤80A | ≤125A | ≤160A | ≤225A | ≤315A | ≤400A | ≤500A | ≤500A |

|

Output voltage range |

|||||||

| 50Vdc~750Vdc | 50Vdc~750Vdc,200Vdc~

750Vdc |

50Vdc~750Vdc | 50Vdc~750Vdc | 200Vdc~750Vdc | 50Vdc~750Vdc | 50Vdc~750Vdc,200Vdc~

750Vdc |

50Vdc~750Vdc |

|

Maximum output current of a single gun |

|||||||

| ≤100A | ≤100A≤150A | ≤200A | ≤250A | ≤250A | ≤250A | ≤250A | ≤250A |

|

Size (mm) 700 (W) x400 (D) x1500 (high) |

Size (mm) 700 (W) x400 (D) x1500 (high) |

Size (mm) 700 (W) x400 (D) x1500 (high) |

Size (mm) 700 (W) x400 (D) x1800 (high) |

Size (mm) 700 (W) x400 (D) x1800 (high) |

Size (mm) 730 (W) x650 (D) x2000 (high) |

Size (mm) 730 (W) x650 (D) x2000 (high) |

Size (mm) 730 (W) x650 (D) x2000 (high) |

|

Weight (kg) System: ≤200kg |

Weight (kg) System: ≤200kg |

Weight (kg) System: ≤200kg |

Weight (kg) System: ≤200kg |

Weight (kg) System: ≤200kg |

Weight (kg) System: ≤250kg |

Weight (kg) System: ≤250kg |

Weight (kg) System: ≤250kg |

|

Parameter class |

Parameter name |

Description |

|

Ac input |

Rated input voltage |

Line voltage 380Vac |

|

Input voltage range |

380±15%Vac |

|

|

Input AC voltage frequency |

50±1Hz |

|

|

Power factor |

≥0.99 |

|

|

Dc output |

Output rated voltage |

750Vdc |

|

Efficiency |

≥94% Rated working condition |

|

|

BMS power supply |

12Vdc and 24Vdc can be configured |

|

|

Background communication interface |

GPRS/ Ethernet |

|

|

Starting charge mode |

Swipe card start APP scan code start |

|

|

Class of protection |

IP54 |

|

|

Security protection |

over and under voltage protection, over current protection, over temperature protection, short circuit protection, ground protection, leakage protection, emergency stop |

|

Wall mounted / column type DC charging pile

|

20KW DC wall-mounted single-gun integrated charging pile |

30KW column DC single-gun integrated charging pile |

||

| Maximum input current ≤40AMaximum output current

of a single gun ≤50A |

Maximum input current ≤63AMaximum output current

of a single gun ≤75A |

||

| Parameter class | Parameter name | Description | |

|

Ac input |

Rated input voltage | Line voltage 380Vac | |

| Input voltage range | 380±15%Vac | ||

| Input ACvoltage frequency | 50±1Hz | ||

| Power factor | ≥0.99 | ||

|

Direct boutput |

Output rated voltage | 750Vdc | |

| Efficiency | ≥94%(rated condition) | ||

| Output voltage range | 200Vdc~750Vdc | ||

|

BMS power supply |

12Vdc | ||

|

Background communication interface |

GPRS/ Ethernet | ||

|

Starting charge mode |

Swipe card startAPP scan code start | ||

|

Mechanical parameter |

Size (mm) |

750 (W) x288 (D) x500 (H) | |

|

Weight (kg) |

System: ≤100kg | ||

|

Class of protection |

IP54 | ||

|

Security protection |

Over and under voltage protection, over current protection, over temperature protection, short circuit protection, ground protection, leakage protection, emergency stop | ||

Ac charging pile series

| 7KW AC single-gun integrated charging pile | 14KW AC double gun charging pile | ||

| Maximum input current ≤32A | Maximum input current ≤80A | ||

|

Dimensions (mm) Weight (kg) |

|||

| 240 (W) x102 (D) x310(H)System: ≤10kg | 280 (W) x127 (D) x400(H)System: ≤13kg | ||

| Parameter class | Parameter name | Description | |

|

Ac input |

Rated input voltage |

Phase voltage 220Vac |

|

| Input voltage range |

220±15%Vac |

||

| Input AC voltage frequency |

50±1Hz |

||

|

Direct output |

Output rated voltage |

220Vac |

|

| Maximum output current of a single gun |

32A |

||

| Output voltage range |

220±15%Vac |

||

|

Background communication interface |

GPRS/ Ethernet |

||

|

Starting charge mode |

Swipe card start APP scan code start |

||

|

Class of protection |

IP54 |

||

|

Security protection |

over and under voltage protection, over current protection, over temperature protection, short circuit protection, ground protection, leakage protection, emergency stop |

||

480KW split DC charging pile

| Parameter class | Parameter name | Description |

|

Complete form |

Split |

Charging host and terminal are designed separately, 1 host +N double gun terminal piles |

|

Ac input |

Power factor |

≥0.99 |

|

Rated input voltage |

Line voltage 380Vac |

|

|

Input voltage range |

380±15%Vac |

|

|

Input AC voltage frequency |

50±1Hz |

|

|

Maximum input current |

≤1000A |

|

|

Ac output |

Output power |

480kW (20n+20m downward customization) |

|

Output rated voltage |

750Vdc |

|

|

Output voltage range |

50Vdc~750Vdc |

|

|

Maximum output current of a single gun |

250A |

|

|

Efficiency |

≥94% (rated condition) |

|

|

Power distribution mode |

Dynamic allocation |

|

|

BMS power supply |

12Vde and 24Vde can be set |

|

|

Background communication interface |

4G/Ethernet |

|

|

Starting charge mode |

Swipe card start /APP scan code start |

|

|

Mechanical parameter |

Host size (mm) |

1400 (W) ×850 (D) ×2200 (H) |

|

Terminal size (mm) |

500 (W) ×240 (D) ×1600 (H) | |

|

Machine weight (kg) |

System: ≤500kg |

|

|

Terminal weight (kg) |

System: ≤100kg |

|

|

Class of protection |

IP54 |

|

|

Security protection |

Over and under voltage protection, over current protection, over temperature protection, short circuit protection, ground protection, leakage protection, emergency stop | |

Non-motor vehicle charging system

| Parameter class | Description |

| Rated input voltage | AC220/50Hz |

| Rated output voltage | AC220/50Hz |

| Number of output circuits | Ten ways |

| Single output power | ≤800W (configurable) |

| Maximum total output power | 5.5 kW |

| Standby power | ≤3W |

| Background communication mode | 5G wireless communication |

| Operating temperature | - 30 ° ℃ to + 50 ℃ |

| Relative humidity | 5%RH~95%RH |

| Class of protection | IP54 |

| Man-machine interface | Key +LED numerical control screen |

10 output, can charge 10 electric vehicles at the same time; Time by time charging, support power three-speed split timing; Support mobile phone scanning code, brush online card, brush offline stored value card, button, background start a variety of charging methods; Intelligent voice prompt, easy to use; With display function, support charging power and other information real-time display, charging time query; Leakage protection, overload power off, full stop, no-load power off and other protection functions; With power failure memory function; With background remote setting function, easy management.

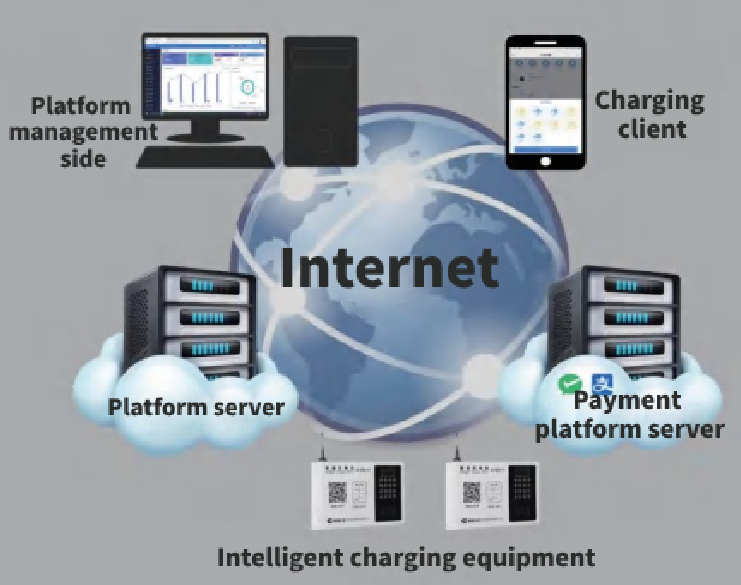

Non-motor vehicle charging station management platform

The platform can monitor the daily status and charging process of the intelligent charging pile of the battery car, and give early warning of abnormal situations in the charging process. Realize charging payment docking, support coin, credit card, wechat pay and other payment methods, ensure the integrity of the payment transaction process, and realize the clearing, settlement and reconciliation functions of the downstream station level platform. The electric vehicle intelligent charging device is connected to the Internet through 2G/50 wireless communication, accesses the intelligent charging management platform, and carries out communication and data interaction with the platform server in the cloud. The charging device uploads the charging pile status information, alarm signals and operation data to the platform server, which is processed by the platform background program on the server to realize the platform's monitoring of the device, recording of operation data, and deducting fees from the user account (online card).

The platform can monitor the daily status and charging process of the intelligent charging pile of the battery car, and give early warning of abnormal situations in the charging process. Realize charging payment docking, support coin, credit card, wechat pay and other payment methods, ensure the integrity of the payment transaction process, and realize the clearing, settlement and reconciliation functions of the downstream station level platform. The electric vehicle intelligent charging device is connected to the Internet through 2G/50 wireless communication, accesses the intelligent charging management platform, and carries out communication and data interaction with the platform server in the cloud. The charging device uploads the charging pile status information, alarm signals and operation data to the platform server, which is processed by the platform background program on the server to realize the platform's monitoring of the device, recording of operation data, and deducting fees from the user account (online card).

The platform server sends control commands to the charging device to realize the remote setting and control of the charging device by the platform, and the response of the scanning code to charge and start the device. Charging users can realize platform user registration, recharge, payment, scanning code charging, etc., through the mobile application. The manager of the platform (charging facility) realizes the remote monitoring, exception handling, and operation parameter setting of the charging equipment through the Web application on the browser side.

The platform server sends control commands to the charging device to realize the remote setting and control of the charging device by the platform, and the response of the scanning code to charge and start the device. Charging users can realize platform user registration, recharge, payment, scanning code charging, etc., through the mobile application. The manager of the platform (charging facility) realizes the remote monitoring, exception handling, and operation parameter setting of the charging equipment through the Web application on the browser side.

Charging users do not need to pay attention to the public account, install the APP and register the user account of the platform, directly use the "scan" to open the charging client application, complete the payment to charge, simple and fast operation, smooth and comfortable use experience; The charging client application provides functions such as finding peripheral charging devices by location, viewing device port usage, navigating to devices and scanning codes for charging.

Electric vehicle intelligent charging operation management system

Electric vehicle charging operation management platform

Electric vehicle charging operation management platform is an Internet-based charging monitoring and operation management platform. It can provide geographical information and location services of charging stations, charging equipment management and monitoring, data collection and fault location, operation statistics and data analysis, multidimensional income data and reports, support a variety of transaction methods such as card swiping and online payment, and meet the needs of different operation management applications such as electric vehicle charging stations and decentralized charging piles.

The EV charging operation management platform adopts a distributed deployment mode, supports private data centers and public cloud platforms, and combines market development and users' actual needs to customize a complete charging operation solution for users.

Electric vehicle charging station integrated monitoring system is based on advanced electronic information technology and Internet technology developed intelligent charging station level monitoring system.

The system adheres to the characteristics of "safe, reliable and flexible" of Dongxu intelligent products, meets the requirements of domestic and industry related standards, adopts distributed architecture and modular service design, and can be flexibly deployed and expanded in combination with market development and practical applications to provide users with a complete comprehensive solution for monitoring at the station level of electric vehicle charging stations.

Intelligent orderly charging control system for electric vehicles

Intelligent orderly charging control system for electric vehicles

The intelligent orderly charging control system of electric vehicles developed by RM manufacturing relies on the models and data of several automation systems of power grid companies that have been built, such as grid dispatching automation system, distribution network automation master station system, and electricity consumption information collection system. Using advanced automated modeling technology, Internet technology, big data technology, etc., with the goal of reliable and safe operation of the power grid, reducing unnecessary investment in the power grid and improving economic benefits, it provides users with effective automatic power distribution and regulation functions of charging stations (charging piles).

Platform description

①Operator management

SAAS service for individual and enterprise users, power station management and user rights can be set, and the implementation of ledger statistics, according to the level of operation to achieve revenue sharing and automatic accounting.

②Authority management

Provides a sophisticated and flexible user rights management mechanism, assigning different platform access rights and device access authorization to specified users, ensuring data security and convenient operation and maintenance.

③Establish and strengthen partnerships/connectivity

To achieve interconnection with mainstream operators, users can use an APP to complete a series of processes such as path planning, vehicle navigation, scanning code charging and payment settlement, making charging easier.

④Platform deployment

With a distributed, modular, and object-oriented design philosophy, it can be deployed in customer-built private clouds, public clouds, or hybrid clouds as needed.

⑤Distribution network management

Integrated distribution network monitoring and control, feeder automation, distribution network work management, distribution network equipment management and distribution network advanced application and other functions, to form a complete distribution management system.

⑥Electric pile access

Supports the connection of AC and DC charging piles of different manufacturers and models, and supports the unified access and management of various manufacturers and types of charging piles under the premise of open communication protocols.

⑦Remote maintenance

Real-time monitoring of the running status of charging piles, support remote diagnosis, maintenance and upgrade, improve equipment reliability, reduce personnel operation and maintenance costs.

⑧Data analysis

Real-time recording of charging information can conduct comprehensive statistical analysis and sequencing of charging amount, charging amount, charging times, operating income and other data of charging stations, providing customers with data support for charging operation decisions

Platform architecture

Control system

System characteristics

①System modular design and flexible deployment.

②Using big data technology, the charging optimization scheme is calculated according to the charging behavior of users and the characteristics of charging facilities.

③The platform is open, which is conducive to the third-party operating platform to timely understand the distribution of charging load.

④Intelligent decision-making, based on historical data and future development decisions, to help users to carry out reasonable distribution transformers and charging facilities of new construction and transformation.

System function

①Data collection, including charging station distribution data, charging pile real-time data, electric vehicle BMS system parameters.

②Real-time computing processing, including statistical analysis, historical data storage, control command delivery, real-time data distribution, computing processing, etc.

③Charging load monitoring: charging power, pile parameters, vehicle parameters, dynamic distribution of charging demand, etc.

④Access to regional power grid related operation information (power, load forecast, power consumption plan).

⑤Operation information about the distribution network in the access area.

⑥Calculation and generation of ordered charging scheme.

⑦Send control commands to the orderly charging control unit, including real-time control commands, short-term load control data, long-term load control data, and other interactive data.

Product characteristics

Product characteristics

The intelligent and orderly charging control device of electric vehicles adopts high-performance, low-power embedded hardware platform and modular software design to manage intelligent charging of electric vehicles, reduce disorderly charging behavior, reduce the cost of charging stations, and maximize the operating benefits of electric vehicle charging stations.

Product function

①Charging real-time monitoring. The monitoring data of the charging process of the charging pile is read, including the charging status, charging voltage, charging current, charging power and alarm information, and the above information is sent to the operation platform through the communication channel.

②Metering and billing monitoring. Under the premise of open metering and billing monitoring data of charging piles, the intelligent orderly charging control device of electric vehicles can realize the reading of metering and billing data during the charging process, and send the above information to the operation platform through the communication channel.

③Charging behavior control. The intelligent and orderly charging control device of electric vehicles can accept the instructions of the operation platform and realize the charging behavior control of the charging pile that accepts the direct scheduling and control of the system, including remote start/stop charging, remote power control, etc.

④Extensible monitoring interface. The electric vehicle intelligent orderly charging control device provides an extensible monitoring interface to communicate with other devices that support the communication protocol of the charge management system, including electricity meters, transmitters, etc., to achieve the monitoring requirements of the operating platform for charging data in different occasions.

⑤Short time scale control. Control the electric vehicles in the area, control the charging start and stop time of the charging pile and control the charging power of the charging pile according to the optimization instruction.

⑤Short time scale control. Control the electric vehicles in the area, control the charging start and stop time of the charging pile and control the charging power of the charging pile according to the optimization instruction.

⑥Optimized control over long time scales. Based on the charging behavior characteristics of electric vehicles in the region, including the charging time of each pile, the battery capacity of electric vehicles, the charging power and other information, a mathematical model is constructed to carry out optimization calculation and generate optimization instructions. The optimization instructions are based on the capacity limit of the distribution network transformer and the analysis and calculation of the user's usage characteristics to obtain the optimal charging time and charging for each charging pile in the future period of time The device has automatic learning function. The richer the characteristics of charging behavior, the more accurate the optimization calculation.

⑦Charging off-peak control. Control the sequence of electric vehicle charging behavior, realize the peak of electric vehicle charging, improve the stability of the power grid: contribute to the power grid peak cutting and valley filling.

Project case