Products

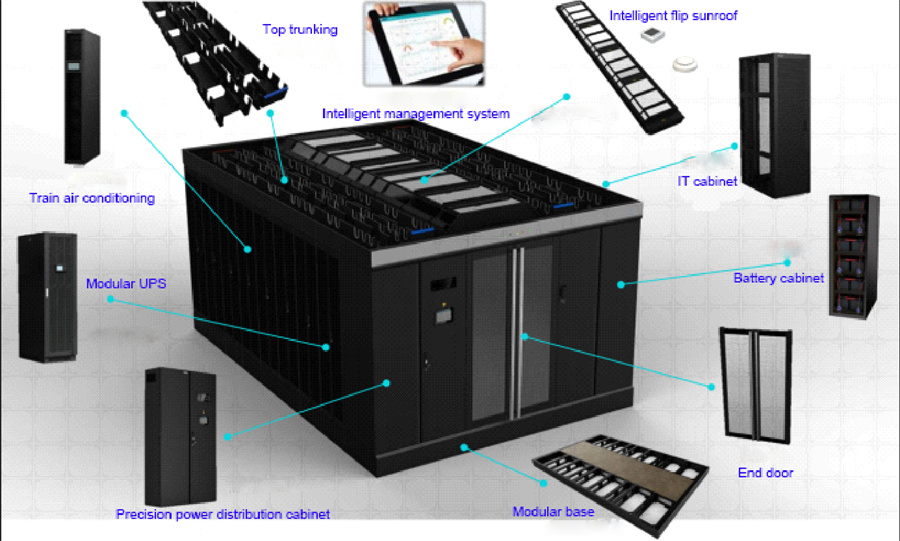

Intelligent modular cabinet RM-IMCB

RM-IMCB series of products aims to solve the problem of 4G and 5G network construction faced by operators from various countries around the world. In terms of construction period and coverage, we have achieved a stage of short construction period and wide coverage. In this situation, we are constrained by the scale of the base station, centralized monitoring and control, energy consumption control, environmental monitoring, energy conservation and emission reduction requirements, including the influence of many factors such as site, machine room appearance, etc., combined with our company’s long-term IDC machine room Based on our experience in the design, production construction, mobile wireless device usage environment, and management requirements of the micro module computer room, our company has designed a new intelligent modular cabinet that fully meets the above requirements, achieving high integration density, stable performance, and centralized monitoring.

Product Application

Rich resources in power grid station sites: Utilize station sites such as substations, office buildings, business halls, warehouses, and workstations, as well as available space resources, to carry out the construction of mobile CRAN machine rooms, aggregation machine rooms, and other facilities.

|

Type of power station |

Space Type |

Area |

Operator Usage |

Device Type |

Number of cabinets |

Device Description |

|

Residential distribution room |

spaces |

<10m² |

OLT Sinking machine room |

300A Power Supply System |

1+1 |

Rated load: 5.8kw Maximum load: 10.8kw Backup time: 3h Air conditioning capacity: 1P |

|

<10m² |

CRAN+OLT Sinking machine room |

600A Power Supply System |

1+2 |

Rated load: 8.6kw Maximum load: 21.6kw Backup time: 3h Air conditioning capacity: 2P |

||

|

10~20m² |

CRAN+OLT Sinking machine room |

600A Power Supply System |

2+3 |

Rated load: 14.3kw Maximum load: 21.6kw Backup time: 3h Air conditioning capacity: 4P |

||

|

Power supply station, substation, business station building |

Independent room |

20~40m² |

Node aggregation machine room |

600A Power Supply System |

2+3 |

Rated load: 14.3kw Maximum load: 21.6kw Backup time: 3h Air conditioning capacity: 4P |

|

≥40m² |

Core aggregation machine room |

1200A Power Supply System |

4 |

Rated load: 28.8kw Maximum load: 43.2kw Backup time: 3h Air conditioning capacity: None (natural air cooling) |

Our company can plan for the 600 model in the early stage and expand to the 1000 model in the later stage based on the needs of each project for this series of products. In principle, the expansion ability is not limited. The expansion aspect includes cabinet capacity expansion and battery energy storage expansion.

Product Function

The RM-IMCB series products designed by our company are aimed at solving the following professional functions for this series of products:

- Professional power supply and distribution system: capable of providing stable AC to DC power output and sufficient backup working hours for power supply.

- Professional monitoring system: achieve centralized and platform based supervision, provide local supervision, and achieve real-time supervision on integrated cabinet door display screens and mobile phones. The system can obtain real-time monitoring data of the computer room infrastructure management system platform through the APP. This mainly includes real-time monitoring data of devices, alarm viewing and statistics, PUE energy consumption data, video image viewing, access control status management, etc.

- Professional temperature control system: The equipment cabinet is equipped with 4.2kw precision air conditioning, which adopts a circulating design inside the cabinet to achieve front air outlet and rear air return, with an air volume of 700m ³/ h. Fully meet the heat dissipation requirements of 8 BBU devices in a single cabinet.

- Professional safety system: the power supply cabinet is equipped with power supply, and the Battery management system can check the power supply online in real time. The battery runs safely and stably. The power supply cabinet and equipment cabinet can be optionally equipped with a fire self extinguishing system to achieve fire safety management. Video surveillance can provide 24-hour online video security monitoring.

Product model classification

| modelparameter |

600 Type |

1000 Type |

|||

|

Single cabinet size |

mm |

1000×600×2200(Depth * Width * Height) |

1000×600×2200(Depth * Width * Height) |

||

|

Cabinet combination |

mm |

Triple connection (power cabinet * 1 unit+equipment cabinet * 2 units) |

Five units (power cabinet * 2 units+equipment cabinet * 3 units) |

||

|

cover an area |

m² |

2 |

3 |

||

|

Installation method |

△ |

Ground |

Ground |

||

|

Ambient Temperature |

℃ |

-40 ~ +55 |

-40 ~ +55 |

||

|

Equipment capacity |

U |

66 |

99 |

||

|

Number of equipment installed |

units |

8 sets of BBUs, 2 sets of transmission equipment, and 1 set of OLT |

15 sets of BBU+2 sets of transmission+1 set of OLT |

||

|

Applicable scenarios |

- |

Small CRAN machine room, capable of OLT sinking, equal to 20 square meters of conventional machine room | Large CRAN computer room, which can be used as a converged computer room, equivalent to a 30 square meter conventional computer room | ||

|

|

Integrated device parameters |

||||

|

AC portion |

Input and output terminals |

AC input: AC380V, 4P/100A × 2-way (mains power and oil engine interlocking) |

|||

|

AC lightning protection |

B级 60KA |

B级 60KA |

|||

|

Battery configuration |

pieces |

6* 48V 100AH batteries |

10* 48V 100AH batteries |

||

|

DC portion |

DC configuration of power cabinet |

12*50AH Efficient rectifier module |

20*50AH Efficient rectifier module |

||

|

DC configuration of equipment cabinet |

2*160A DC distribution unit |

4*160A DC distribution unit |

|||

|

output |

4*63A/1P,4*32A/1P |

4*63A/1P,4*32A/1P |

|||

|

Dynamic environmental monitoring |

hardware configuration |

Monitoring host+11.6-inch LCD display screen |

|||

|

function |

Monitoring unit, power supply, battery, air conditioning, emergency cooling system monitoring, door magnet, water immersion sensor, smoke sensor, temperature and humidity sensor | ||||

|

Temperature control equipment |

Emergency cooling system |

Electric air valve+emergency fan |

Electric air valve+emergency fan |

||

|

air-conditioning |

1.5 horsepower wall mounted air conditioning |

One equipment cabinet equipped with one 4.2kw rack mounted precision air conditioner |

|||

|

ODF |

Optional |

Optional according to equipment requirements (independent ODF rack can be used) |

|||

|

Intelligent fire protection |

Optional |

The cabinet is equipped with an embedded heptafluoropropane fire extinguishing device (automatically activated when the temperature exceeds 68 ℃), which has no corrosion to electronic equipment and is non-toxic to the human body |

|||

|

monitor |

Optional |

The cabinet is equipped with a built-in or external monitoring system, which cooperates with the dynamic loop system to complete real-time alarm monitoring |

|||

600 Type Cabinet

1000 Type Cabinet

Introduction to Single Cabinet

Power cabinet

Battery cabinet

Equipment cabinet

Management system

The monitoring and management system mainly monitors and manages the equipment and environment inside the integrated cabinet. Both the integrated cabinet end and the monitoring center end can manage the integrated cabinet, and an independent touch screen is set up outside the integrated cabinet.

Packaging and transportation

- High integration: Support integrated management and monitoring of power supply, energy storage, dynamic environment monitoring, equipment, and temperature control

- High reliability: High safety Lithium iron phosphate battery is used in combination with self-developed battery intelligent charge and discharge management system

- High reliability: The cabinet power supply is configured in N+2 mode, supporting oil engine interface

- Smart energy consumption: The high-efficiency rectifier module used in the AC/DC system has a rectification efficiency of over 97%

- Intelligent temperature control: The cabinet adopts precision rack type air conditioning, and the heating equipment has a complete closed air duct structure, which can achieve precise heat dissipation

- Smart monitoring: The system adopts a visual monitoring platform, implements a 7 * 24-hour duty system, and has voice and SMS alarm reminder functions

- Real time supervision: The system can obtain real-time monitoring data of the computer room infrastructure management system platform through the APP

- Warning function: Early warning, such as insufficient cold night air conditioning, power failure, and insufficient battery capacity, the system notifies maintenance personnel

- Intelligent fire fighting: the cabinet is equipped with fire fighting module, which can cooperate with smoke sensing and temperature sensing starting equipment to Automatic fire suppression

Application Cases

Packaging and transportation

RM-IMCB series cabinet will adopt export fumigation wooden box during overseas business transportation. The wooden box adopts a fully enclosed structure, and the bottom uses a forklift tray, which can ensure that the cabinet will not be damaged or deformed during long-distance transportation.

Product Services

Customized service: our company design and manufacture of the RM-IMCB series Cabinets, can provide customers with customized design, including product size, function partition, equipment integration and control integration, materials custom, and other functions.

Guidance services: the purchase of my company's products to customers to enjoy life-long product use guidance services, including the transportation, installation, application, disassembly.

After sales service: Our company provides remote video and voice after-sales online services, as well as lifelong paid replacement services for spare parts.

Technical service: our company can provide every customer with complete pre-sale service, including prophase technical solution discussion, finalize the design, configuration, and other services.

The RM-IMCB series cabinets can be suitable for multiple industry applications, including communication, power, transportation, energy, security, etc.