Cable tray is the weak current system of intelligent buildings, usually composed of multiple information monitoring and communication facilities such as BA (Building Automation), OA (Office Automation), CA (Communication Automation) and other corresponding systems. Cable tray is divided into trough, tray and ladder structures, consisting of brackets, support arms and installation accessories. When selecting, attention should be paid to whether all components of the bridge meet the requirements of serialization, generalization, and standardization as a complete set. The bridge frame inside the building can be independently erected or attached to various building and pipe gallery supports. It should reflect the characteristics of simple structure, beautiful appearance, flexible configuration, and easy maintenance. All parts need to be galvanized. The bridge frame installed outside the building in the open air must have anti-corrosion and moisture resistance materials if it is near the seaside or in a corrosive area.

What are the styles of cable trays?

1. Cascade cable tray

The CQ1-T stepped cable tray is an improved design based on relevant domestic and foreign data. It has the advantages of light weight, low cost, unique design, easy installation, heat dissipation, and good breathability. It is suitable for laying cables with larger diameters and for laying high and low voltage power cables.

Tray type cable tray is widely used in petroleum, chemical, light industry, telecommunications and other fields. It has the advantages of light weight, large load capacity, beautiful appearance, simple structure, and easy installation. It is suitable for both the installation of power cables and the laying of control cables.

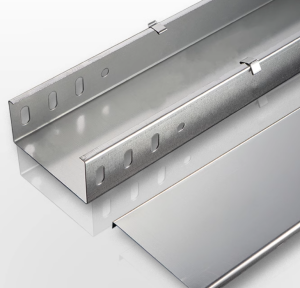

3. Slotted cable tray

Trough type cable tray is a fully enclosed cable tray. It is suitable for laying computer cables, communication cables, thermocouple cables, and control cables for other high-sensitivity systems. It has good effects on shielding interference of control cables and protecting cables in environments with heavy corrosion.

The advantages and disadvantages of stepped, tray, and trough cable trays are as follows: stepped cable trays have good ventilation performance, are not dustproof, and are not resistant to interference. The trough and tray type cable trays have dust-proof and anti-interference properties.

4. Large span cable tray

The current large-span cable trays are generally assembled from extruded fiberglass profiles and are suitable for power cables, control cables, lighting cables, and accessories. Compared with iron cable trays, it has the advantages of long service life (generally designed for 20 years), easy installation and low cost (with a specific gravity of only 1/4 of carbon steel, no need for hot work during construction, and a single cable tray length of up to 8 meters or even longer), convenient cutting, and no maintenance required.

Composite cable tray is a new type of cable tray and the second generation product in the cable tray series. It is suitable for laying various projects, units, and cables. It has the characteristics of simple structure, flexible configuration, easy installation, and novel form.

Post time: Nov-06-2024