Our factory uses Germany TRUMPF Baichao, Japan AMADA laser cutting machine, power 3000w, processing speed 10 meters/min. It can be used for the blanking of medium and thick plates, without the need to use molds, and can be processed for any shape of steel plates, without burrs, smooth surface and high production efficiency.

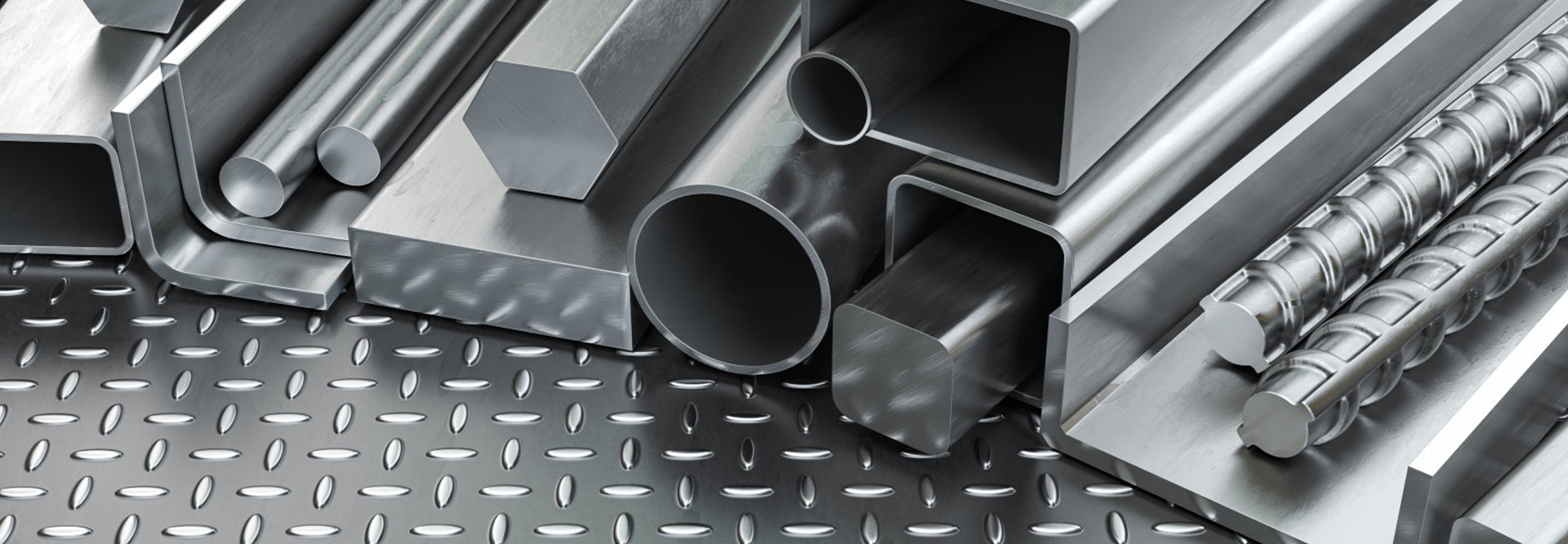

Our factory has 11 sets of three-axis, 4 sets of five-axis CNC machining center, and 5 sets of CNC lathes and other corresponding equipment, processing accuracy of ±0.01mm, processing range: stainless steel, aluminum alloy, brass, copper, ABS, PC, POM, PMMA, Teflon and other materials

Our factory has 19 AMADA, ACCURPRESS CNC bending machines, which can process 0.2-22.0mm thickness. 3.2m sheet metal, processing accuracy ±0.1mm. Including but not limited to iron, stainless steel, galvanized plate, electrolytic plate, aluminum, cold rolled plate and so on. It has the advantages of high precision and fast speed.

The sheet metal processing plant has 3 welding lines and 2 automatic welding lines with mechanical arm, which can carry out argon arc welding, carbon dioxide welding and laser welding. The welding efficiency is high, the finished product is firm, and the thick and thin plates can be welded. In addition, there are 8 grinding and polishing machines, after grinding, the welding joint is smooth and beautiful, and the polishing mirror reaches 8k effect.

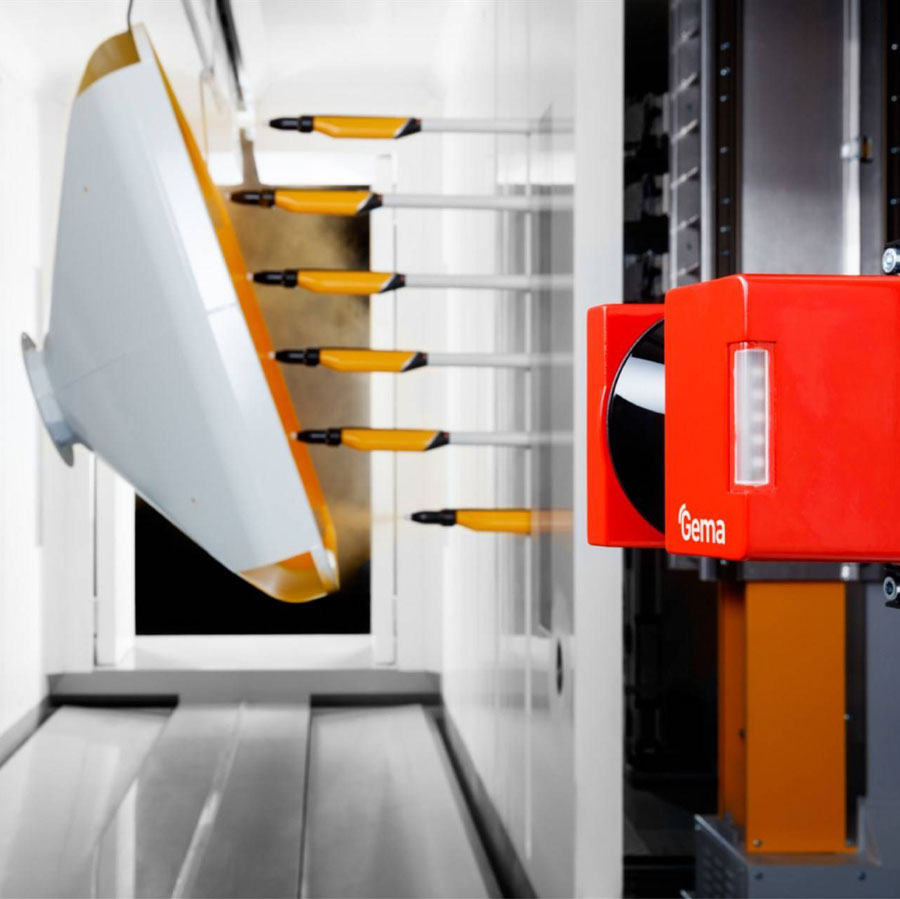

Our company has two powder production lines, the product after rust removal, pickling, phosphating and other 9 pre-treatment processes into the spray room electrostatic spraying, and then after 200 degrees of high temperature will melt the powder adsorbed on the surface of the product, in order to achieve rust, corrosion, beautiful and other effects, and in line with international environmental standards, will not produce toxic gases.

Different from the general sheet metal processing plant, our company has two electronic assembly lines, a number of electronic technical engineers, equipped with automatic riveting machine, high efficiency, high quality and stability of riveted products. Electrical assembly in strict accordance with the electrical component layout, wiring diagram and technical requirements of the process to install electrical appliances, in line with the standardization requirements of the state or enterprise.