Introduction to Sheet Metal Welding

- Electrostatic spraying is a spraying method that utilizes a high-voltage electrostatic field to cause negatively charged coating particles to move in the opposite direction of the electric field and adsorb the coating particles on the surface of the workpiece.

- Before spraying the product, we need to first polish, sand, clean, and then remove the oil and rust on the surface of the product through acid pickling and phosphating, which is beneficial for improving the adhesion of the spraying coating.

- We have a Swiss Kinmar fully automatic spraying assembly line and a German Wagner fully automatic spraying assembly line, which can better serve and improve product quality and efficiency.

Service method

The powders we use for surface treatment are all international brands, such as DuPont Huajia, TIGER from Austria, and Aksu from the Netherlands. We support customers to provide various types of color cards and customize powder colors. The color cards support international standards such as Lauer and Pantone, and powder glossiness, particle size, and mixed materials can be customized

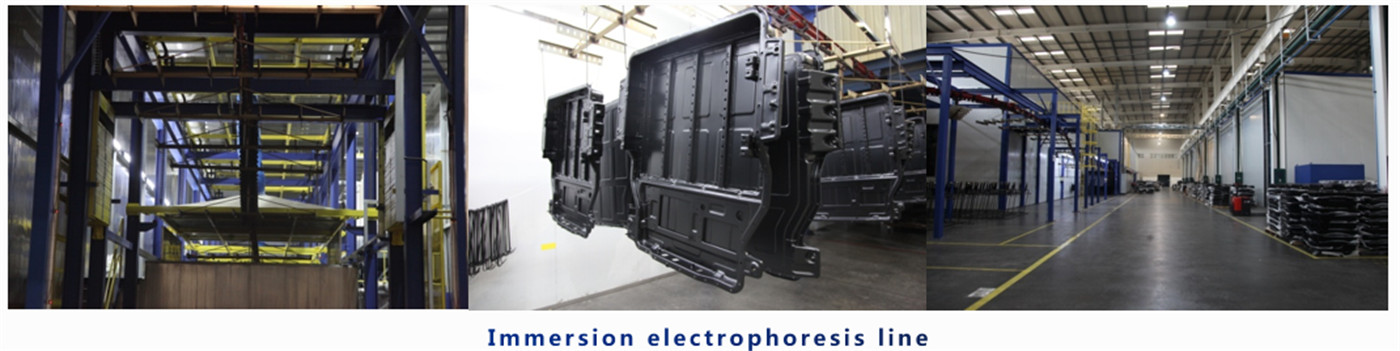

Our equipment

Product display diagram