Introduction to Laser Cutting Technology

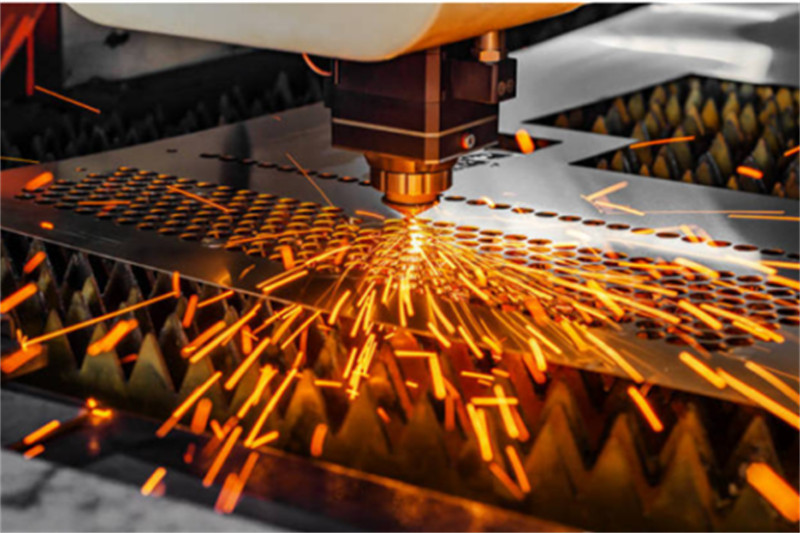

- Laser cutting technology is the most common processing method in sheet metal processing, which has advantages such as high accuracy, fast speed, no need for molds, and smooth cutting surfaces.

- Sheet metal laser cutting is mainly processed and cut by laser cutting machines to ensure the accuracy and quality of the product.

- We provide a one-stop sheet metal laser cutting solution to make production more efficient.

- Our factory has German Tongkuai laser cutting machine and Tiantian LCT-3015AJ laser cutting machine, with a power of 3000W.

- Can process various materials such as cold plates, stainless steel plates, electrolytic plates, galvanized plates, aluminum plates, etc.

- The cutting thickness is 0.5-10mm.

Service method

We have professional equipment and technical personnel to meet any of your processing needs. You only need to provide design drawings and technical requirements, and we support any processing. Various specifications can meet your various needs. It has a wide range of applications, which can be applied to various industries such as construction, medical, railway, communication, etc. We support the design drafts of the following design software

Our equipment

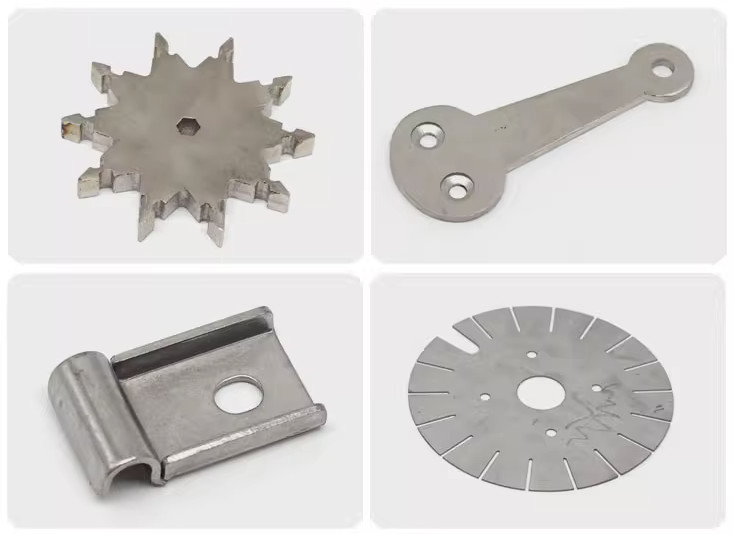

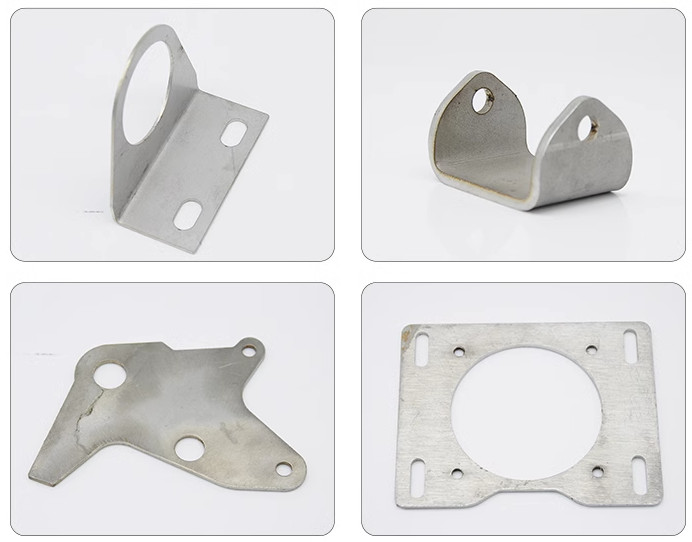

Product display diagram