Introduction to Sheet Metal Welding

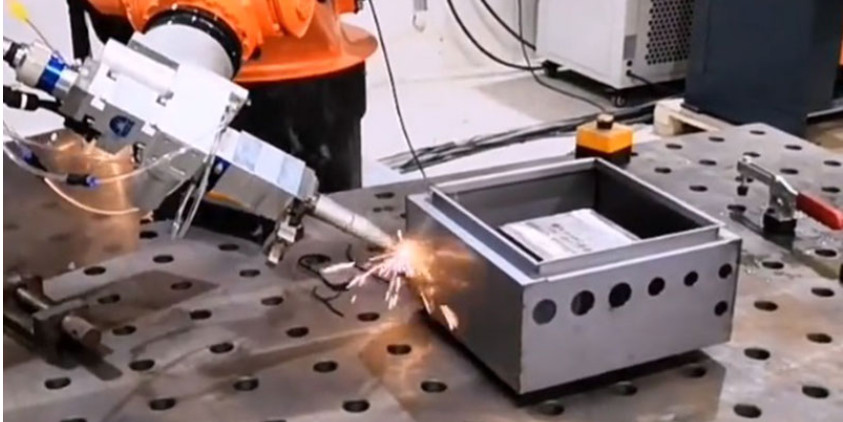

- Welding refers to a processing process in which two or more metal or non-metallic parts are fused by heating to form a solid whole. In sheet metal welding, the most commonly used methods include manual arc welding, gas shielded welding, and spot welding.

- We support customized processing services, and welding services are a part of our services. Here, we can achieve integrated product molding and finished product processing without the need for secondary transportation and processing.

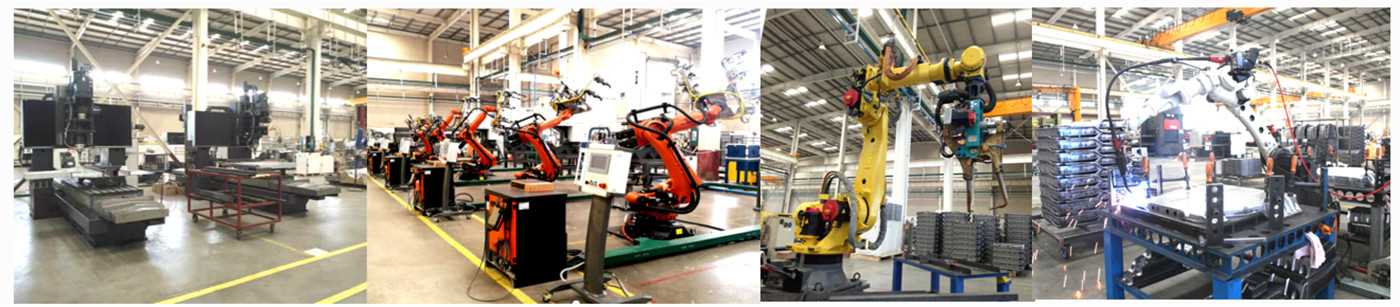

- We have 5 high-precision welding platforms and various types of welding equipment, including 5 carbon dioxide shielded welding, 2 manual arc welding, 2 spot welding machines, 2 handheld laser welding, 1 Farak R-2000A resistance welding robot, 1 Shanghai Anchuan DX200 aluminum welding robot, and 20 Panasonic TM-1800A welding robots.

- We have a professional welding team, and the technical team can solve the difficulties you encounter on your product.

Service method

We have professional equipment and technical personnel to meet any of your processing needs. You only need to provide design drawings and technical requirements, and we support any processing. Various specifications can meet your various needs. It has a wide range of applications, which can be applied to various industries such as construction, medical, railway, communication, etc. We support the design drafts of the following design software.

Our equipment

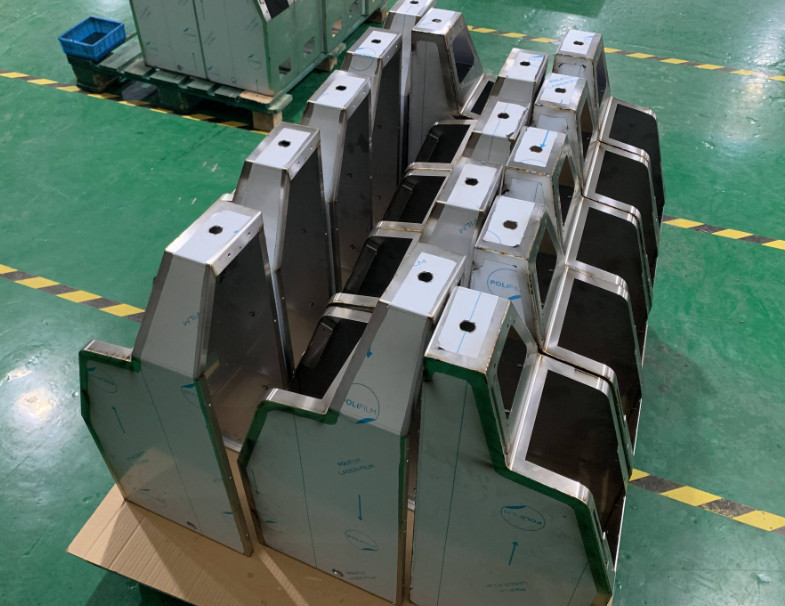

Product display diagram